Allonic Raises €6M For Robotic Body Manufacturing Platform With OpenAI Support

Feb 11, 2026 | By Kailee Rainse

Budapest-based robotics startup Allonic has raised €6 million ($7.2 million) in pre-seed funding to industrialize a novel approach for producing complex, dexterous robotic bodies through its manufacturing platform.

SUMMARY

- Budapest-based robotics startup Allonic has raised €6 million ($7.2 million) in pre-seed funding to industrialize a novel approach for producing complex, dexterous robotic bodies through its manufacturing platform.

The round was led by Visionaries Club, with participation from Day One Capital, Prototype, SDAC Ventures, and TinyVC, alongside over a dozen angel investors, including OpenAI and Hugging Face, and top research institutions like ETH Zurich and Northwestern University. It is reportedly Hungary’s largest pre-seed financing to date.

“A lot of attention is on intelligence and software, but hardware still holds many of the hardest problems,” says Benedek Tasi, co-founder and CEO of Allonic. “The trade-offs between durability and softness, dexterity and strength have always been dictated by the limits of manufacturing. We are removing those constraints and building a platform that allows robotics teams to design, build and iterate freely, without hardware cost or complexity holding them back.”

Founded in 2021, Allonic is a robotics hardware company pioneering 3D Tissue Braiding, a fully automated manufacturing platform for creating integrated, compliant, bio-inspired robotic bodies. By replacing assembly-heavy designs and complex supply chains, Allonic enables faster iteration, lower costs, and safer, more dexterous robots.

RECOMMENDED FOR YOU

[Funding alert] London-based Anima Secures €11 Million in Series A Round Funding

Team SR

Mar 19, 2024

[Funding alert] Amsterdam-based Renewaball Secures €3 Million in Funding

Team SR

Apr 12, 2024

Forest funding news – London-based Forest Secures €15.3 Million in Series B Round Funding

Kailee Rainse

Jan 23, 2025

Read Also - Navro Appoints Anna Andreeva As New Chief Financial Officer

Most advanced robots today are still assembled manually from hundreds of precision parts, making them expensive, hard to customize, and difficult to scale. While AI has revolutionized robot intelligence, their physical construction remains rooted in industrial-era methods rigid parts, bearings, screws, cables, and delicate joints. Increased functional demands only heighten mechanical complexity, limiting dexterity, robustness, and human-safety.

Allonic addresses this at the manufacturing infrastructure layer. Its proprietary process 3D-weaves robotic “tissues” over a skeletal core, forming tendons, joints and load-bearing soft tissues in a single, continuous operation. Inspired by human connective tissue, the approach replaces hundreds of assembled parts with integrated structures.

The platform combines hardware and software that translates high-level robotic designs into production code similar to 3D printing slicing. Multiple materials elastics, wiring and sensors can be embedded directly into robotic bodies during fabrication producing limbs or manipulators straight from digital designs without complex supply chains.

This new approach allows manufacturers, startups, and researchers to design, produce, and replace robotic components on demand. End effectors can be swapped as easily as disposable gloves, making customized, high-performance hardware economically viable for the first time.

“Robotics has reached a tipping point,” says Marton Sarkadi Nagy, Partner at Visionaries Club. “The gap between sophisticated, AI-driven software and slow hardware manufacturing is now a limiting factor for the entire industry. Allonic is the first company I’ve seen to address this problem at the infrastructure layer. By rethinking how robotic bodies are built from scratch, they open the door to faster iteration, lower costs, and robots that will finally be able to move beyond narrow industrial use cases.”

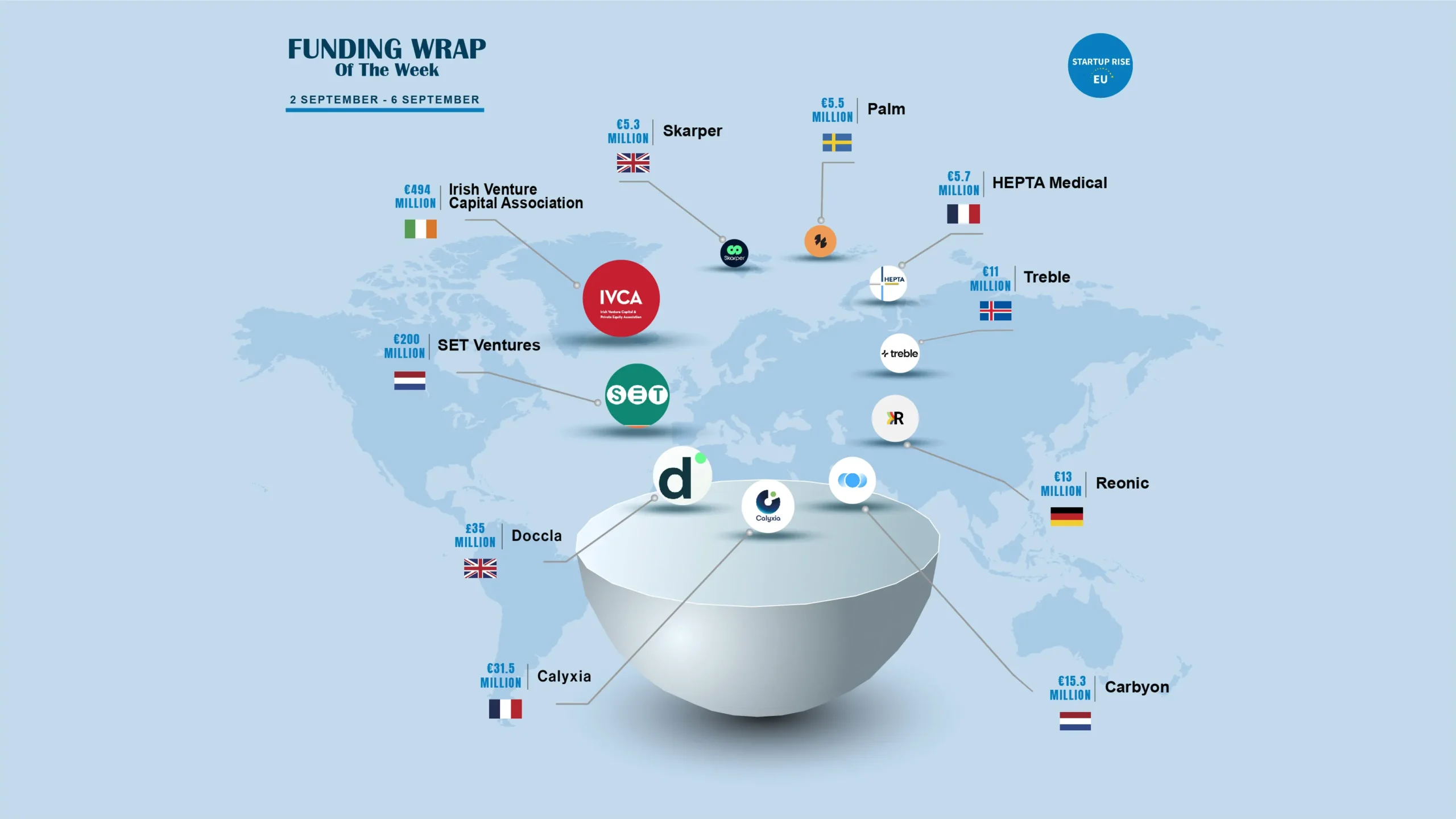

In the broader European robotics and physical-AI funding landscape of 2025–2026, Allonic’s pre-seed round reflects a growing flow of capital into both hardware-focused and enabling robotics technologies.

In 2025 Gravis Robotics (Zurich) raised €19 million to scale autonomous robotic excavators, while Swiss startup mimic secured €13.8 million to develop dexterous robotic systems. Zurich-based Flexion closed a €43 million Series A for cognitive and control systems for humanoid and autonomous robots.

On the autonomy and software side, Germany’s Energy Robotics raised €11.5 million for autonomous inspection robots and drones, and London-based Neuracore raised €2.5 million pre-seed to build unified robot-learning infrastructure.

In adjacent application areas, Warsaw-based Nomagic raised €8.3 million to scale physical-AI deployments, Dutch startup SAIA Agrobotics secured €10 million for greenhouse automation and UK-based ScrubMarine raised €849k pre-seed for subsea robotics.

These disclosed rounds total roughly €98 million invested in European robotics and physical-AI startups during the period. Against this backdrop, Allonic’s Hungary-based pre-seed funding is notable for its size at an early stage and its focus on robotic manufacturing infrastructure, a segment that has seen comparatively fewer large early-stage investments than application or software layers.

“Being able to go from idea to physical robot in minutes instead of weeks fundamentally changes how we can think about robotics design,” Benedek adds. “Once that barrier disappears, entirely new classes of robots become possible.”

Since unveiling its technology in May 2025 Allonic has completed its first pilot in electronics manufacturing, tackling tasks where traditional industrial robots lack flexibility and general-purpose robotic platforms remain costly or impractical at scale.

The new funding will accelerate development of Allonic’s 3D Tissue Braiding platform, expand engineering and operations teams and support additional pilots and early commercial deployments with industrial partners.

Follow us

Follow us Follow us

Follow us