AI Startup 36ZERO Vision Secures €3.6M For Visual Quality Automation

Jul 15, 2025 | By Kailee Rainse

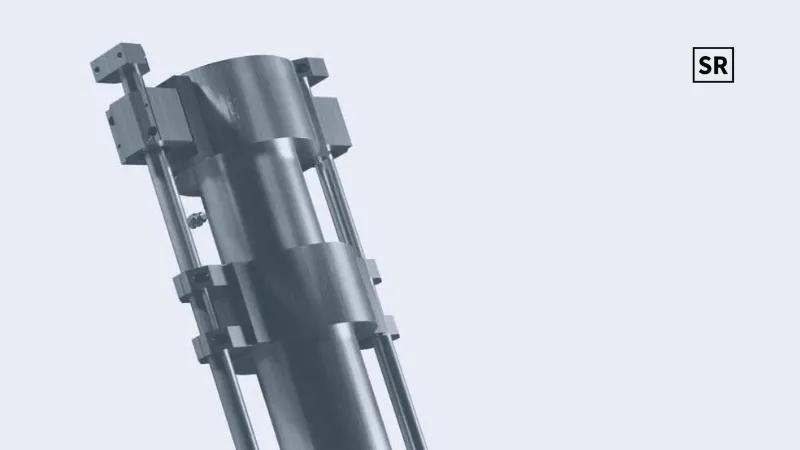

36ZERO Vision, a Munich-based startup focused on visual quality inspection, has raised €3.6 million in pre-Series A funding to scale its AI-powered vision operating system for manufacturing.

SUMMARY

- 36ZERO Vision, a Munich-based startup focused on visual quality inspection, has raised €3.6 million in pre-Series A funding to scale its AI-powered vision operating system for manufacturing.

Their software-defined, hardware-agnostic platform is known for its high accuracy and user-friendly design. It significantly reduces false positives (pseudo defects), a common issue with traditional inspection tools.

The funding will help expand its market reach, as the company continues improving inspection reliability across industrial operations.

Read Also - German HRTech Ordio Secures €12 Million In Series A Round

RECOMMENDED FOR YOU

[Funding alert] Utrecht-based Solvimon Secures €9 Million in Seed Funding

Team SR

Nov 14, 2023

Forest funding news – London-based Forest Secures €15.3 Million in Series B Round Funding

Kailee Rainse

Jan 23, 2025

CEO Heiko Huber and co-founder/CTO Zeeshan Karamat shared more about their mission to transform quality control in manufacturing through smarter, scalable AI solutions.

Co-founder and CTO Karamat has a background in mathematics and computer science with a strong entrepreneurial mindset and work ethic. He shared:

“Even during high school, I was freelancing, working for some of the top 100 companies globally. I was also among the top three students in a national math competition in Pakistan.

I had this extreme learning phase — working up to 22 hours a day using what I called the “Superman pattern”: four hours of work, 20 minutes of sleep, and repeating it five times.

After that, I applied to Stanford and was lucky enough to be accepted, but due to my nationality at the time, I couldn’t get the visa. So instead, I applied to universities in Australia and Germany. In Germany, tuition was free, so it was an easy choice.”

He began his career at Microsoft and later joined the BMW Group, where he led a predictive maintenance project that accurately predicted machine failures 9–10 weeks in advance. While the project was a success, he realized the corporate 9-to-5 life wasn’t his calling.

On weekends, he immersed himself in hackathons—MIT, Oxford, Microsoft—and won over 100 times.

One of those hackathons at BMW sparked the idea for 36ZERO Vision, where his team set out to build a software-only industrial quality inspection system, using minimal hardware to keep the solution scalable and efficient.

According to Zeeshan, the startup originally began using iPhones because they're accessible and easy for customers to deploy without any specialised hardware:

“Our tech stack was developed with low-end hardware in mind. We rewrote the entire foundation model in C++, optimised to run efficiently even on devices like iPhones, NVIDIA Jetson units, or low-spec GPUs.

We support industry protocols like GenICam, which allows us to connect to a wide range of industrial cameras — Matrix Vision, IDS, etc.On the compute side, we use low-level languages to ensure maximum efficiency.”

36ZERO Vision leverages deep learning to detect patterns in manufacturing, unaffected by background noise or lighting conditions. Its model learns from real images and can also generate hundreds of thousands of synthetic images based on key variations, improving performance and scalability.

At the heart of the system is a multi-stage foundation model, built like a "mixture of experts". Each stage is trained on a specific task, allowing individual components to master smaller details. Together they deliver highly accurate results.

Currently, the model is trained on 2D visual images, ranging from single-channel to five- or six-channel inputs.

According to Zeehan, “these could be standard RGB images, mono cameras, or even X-rays.”

“The powerful part is that we only need a small number of data points, sometimes as few as five images.

In one benchmark with just 10 images, we achieved nearly perfect accuracy — no missed defects, no false alarms. In contrast, a state-of-the-art competitor had a 9 per cent error rate. Our platform is highly data-efficient.”

About 36ZERO Vision

Founded in 2021, 36ZERO Vision is transforming quality assurance with easy-to-use AI tools for manufacturers. Its powerful algorithm detects pixel-level defects with just a few clicks, improving accuracy, productivity and efficiency—while reducing the need for resources. The goal: smarter, more accessible quality control for all manufacturing operations.

Follow us

Follow us Follow us

Follow us